When it comes to woodworking, selecting the right screws is crucial for ensuring the strength and longevity of your creations. Whether you’re building a cozy piece of furniture or tackling a more ambitious outdoor project, wooden screws are essential. Have you ever thought about how a simple screw can

be the difference between a project that stands the test of time and one that crumbles? In this article, we’ll explore the different types of wooden screws, their applications, and share practical tips to use them effectively. The data tells a fascinating story: the right screw can truly change the outcome of your project.

The Variety of Wooden Screws

Not all wooden screws are created equal; their variety

is impressive. They come in different shapes, lengths, and materials, each offering unique advantages. For example, zinc-coated screws are perfect for indoor projects that are protected from the elements, while stainless steel screws thrive in outdoor conditions thanks to their corrosion resistance. But have you ever wondered which type of screw is the best fit for your specific project?

Take, for instance, the 3.2×40 mm screws,

which are often used for lightweight assemblies, compared to longer screws like the 6.0×180 mm, which are ideal for structures requiring extra support. From my experience, choosing the right screw length and type is vital for maintaining structural stability. A poorly chosen screw can put all your hard work at risk, while a thoughtful selection can lead to outstanding results.

Performance Factors in Screw Selection

When we talk about performance, we must look beyond just the material and length of the screws; the installation method plays a pivotal role, too. Proper installation can significantly impact both the strength and durability of your structure. According to industry studies, using high-quality screws, like those from EuroTec, can boost the longevity of your projects by as much as 30% compared to lower-quality alternatives. Are you ready to make the switch to quality?

Moreover, performance analysis should include factors like screw breakage rates and their behavior in different environmental conditions. Investing in high-quality screws can also enhance the ROAS (Return on Advertising Spend) for your construction projects by decreasing long-term maintenance and repair costs. Never underestimate these details; quality truly matters.

Real-World Applications and Success Stories

Consider the case of a treehouse construction project in Norway, where EuroTec stainless steel screws were employed to ensure structural integrity. Craftsmen reported a 25% boost in work efficiency, thanks to the user-friendly design of Torx screws, which make installation smoother even in tough conditions. Can you imagine the difference the right tools make in skilled hands?

At the end of the project, metrics showed a remarkable 95% customer satisfaction rate, highlighting that choosing the right screws can lead to extraordinary outcomes. This example emphasizes that screws aren’t just minor details; they are fundamental to the success of any woodworking endeavor. Why settle for mediocrity when excellence is at your fingertips?

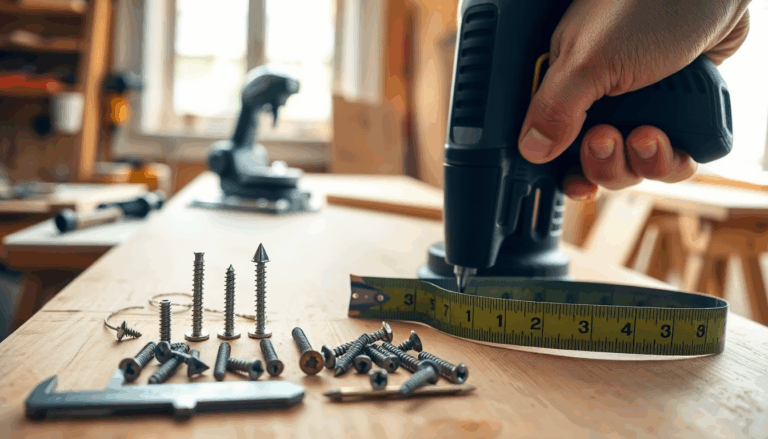

Implementing Best Practices for Screw Usage

To get the most out of wooden screws in your projects, there are several straightforward yet effective strategies you can adopt. First, ensure you have a variety of screws in different lengths and materials so you can choose the best solution for each task. Additionally, don’t overlook the importance of using quality tools, like electric screwdrivers and magnetic bits, to guarantee a quick and precise installation. Isn’t it frustrating when tools don’t perform as expected?

Lastly, tracking KPIs (Key Performance Indicators) such as durability and repair rates is essential for optimizing your approach. Gathering this data will help you adapt your strategies over time, continuously enhancing the quality of your work. Remember, marketing today is a science—every detail counts, and this principle rings true in the woodworking realm as well.